AI Solutions for Wood Industry

So far, our focus has been from various sectors mainly on wood industry. Technologically we are using cameras and 3D lasers for capturing the material, applying additionally detection software that has been developed to artificial intelligence.

We have capacity to build different lines and we take the full responsibility for the delivered installation

Each solution is unique, created based on the customer’s requirements and the choice of technology is made according to the manufacturing conditions and executed by our specialists with care and professionalism.

Read in more detail about Leanest Scanner 2.0 and technology here.

Manufacturing Optimization

AI Solutions in Industry

Workforce Planning

Delivered Projects

Leanest has delivered various solutions based on AI technology to Estonian wood industry companies.

Some examples:

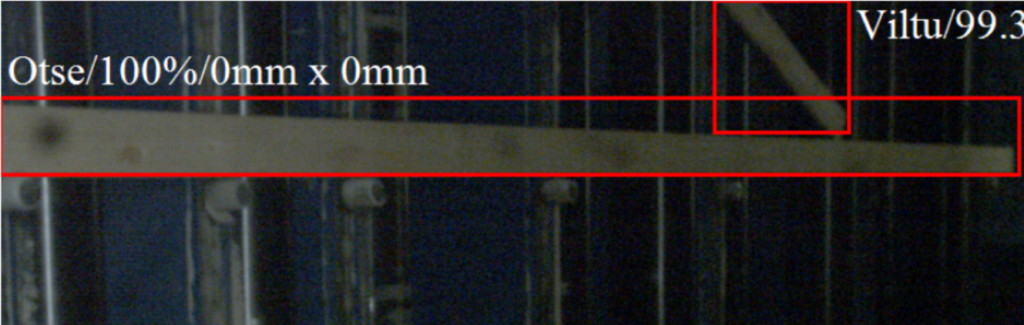

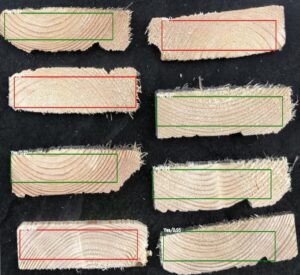

Automated quality control of wooden slat

In the process of quality control of wooden slat, it is important to identify even the smallest defects: cracks, holes, branches, cracks, glue points, etc. In this example, the wood is less than 10cm wide and defects are detected with a scale of less than 1mm. We designed and delivered both the device and the software for automated quality control system.

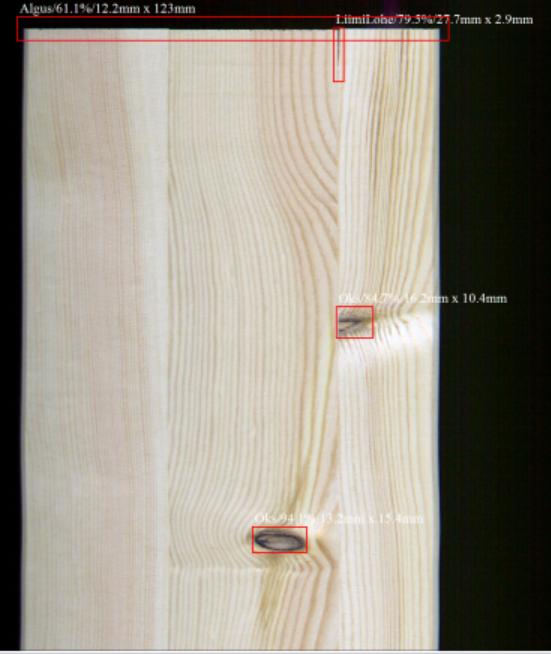

Automated quality control of planed board

In case of determination of the quality class of the planed board – the detection of the defects must be completed first (different types of knots – light knot, dark knot, rotten knot) cracks and splits, bark, length and thickness of the resinous, in total more than 20 different defects – only thereafter the determination of the class can be done.

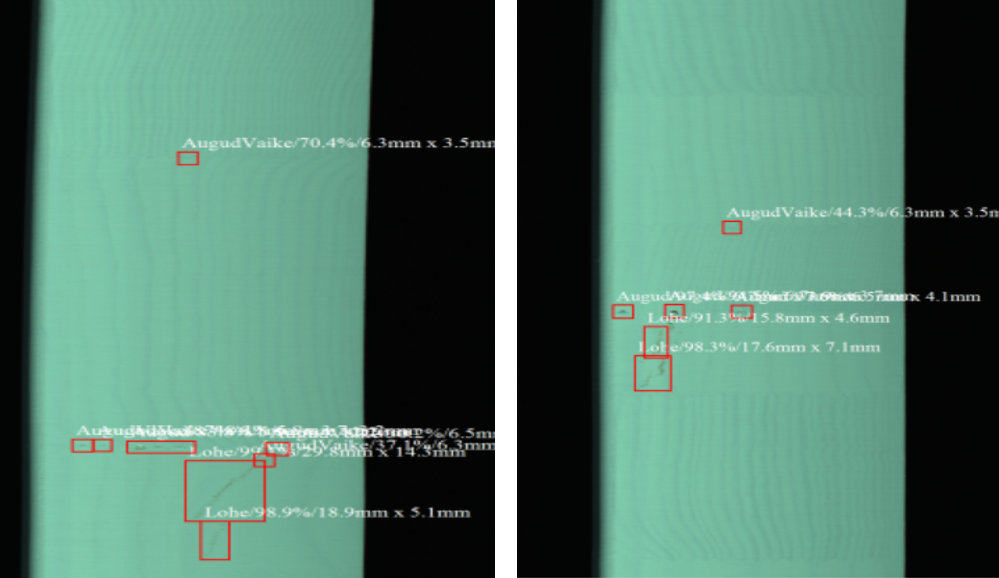

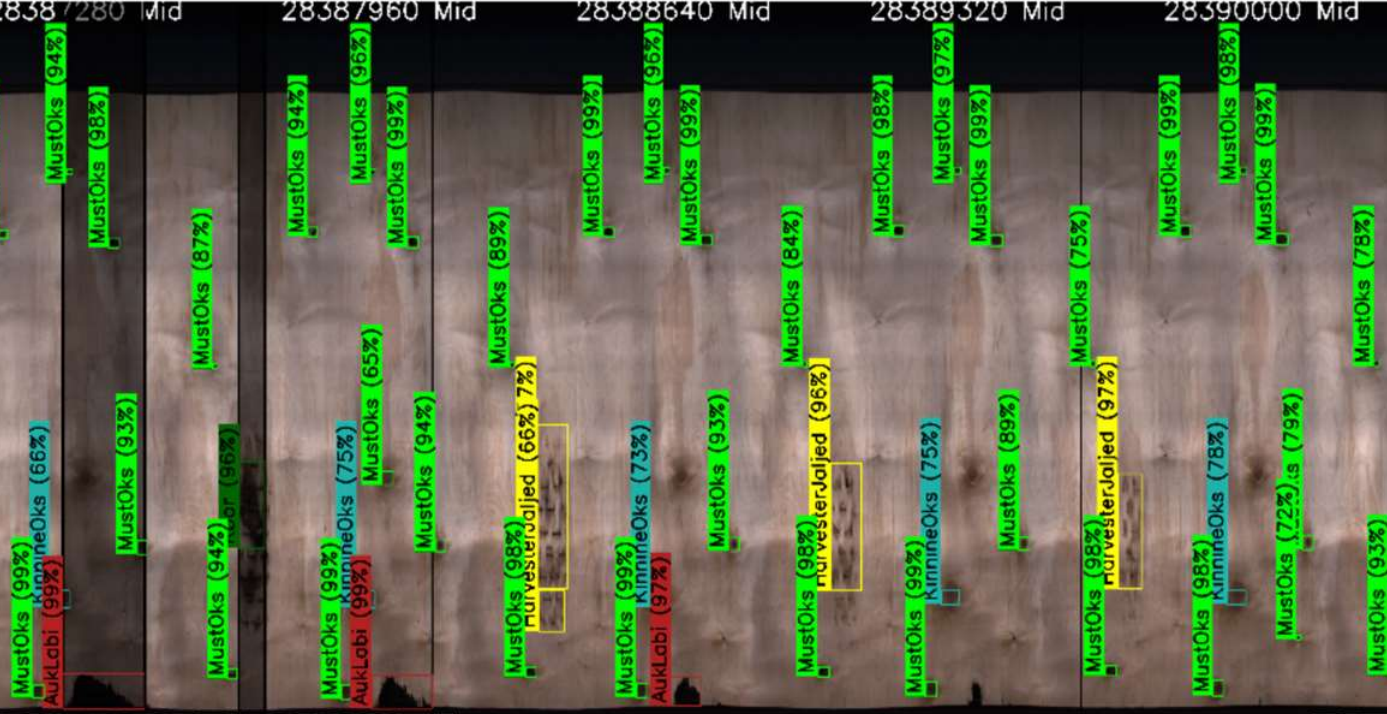

Veneer quality control and cutting system – We have designed and delivered a quality control solution for veneer production, where AI technology detects defects on the material (e.g. heartwood, cracks, holes, bark, rot, harvester marks and various knots) and according to the set quality matrix, the system divides the veneer into the most optimal cutting of sheets (different widths, strips, scrap). The material movement speed is up to 160 m/min.

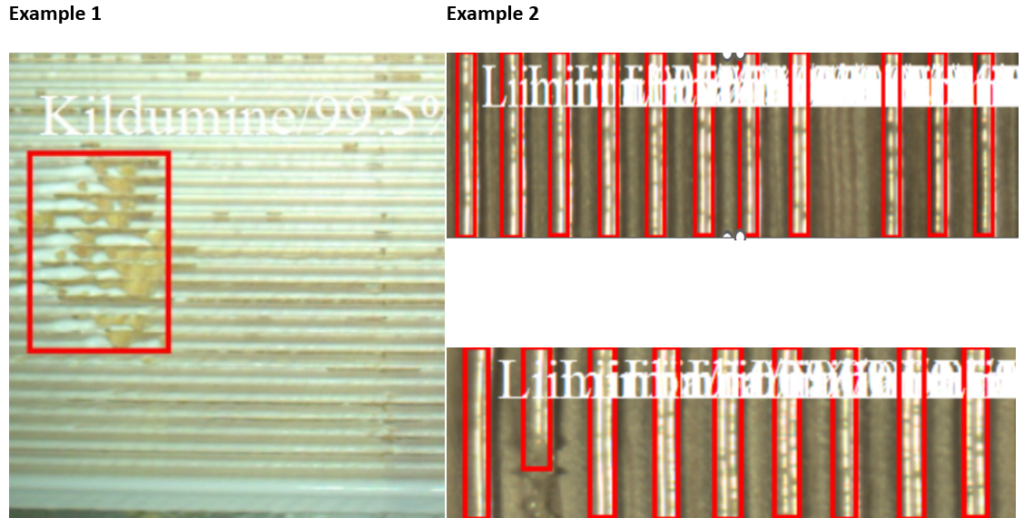

Detection of annual rings’ direction

Detection of annual rings’ direction – we have created the software solution and supplied the equipment that can be used to detect the direction of annual rings on wood. In the manufacturing, the board is turned according to the annual rings.

Automated glue coating controlling system

We have developed the detection software and supplied our customers with the line for glue controlling, which checks whether enough glue has been applied to the surface of the parts.

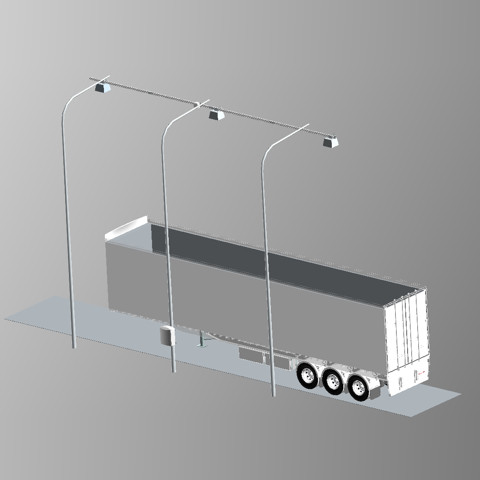

Measurement of the load capacity

We have designed a complete solution for measuring the volume of the load of sawdust and wood chips. Our solution is based on the image of 3D cameras, on the basis of which the load volume in cubic meters is automatically calculated.

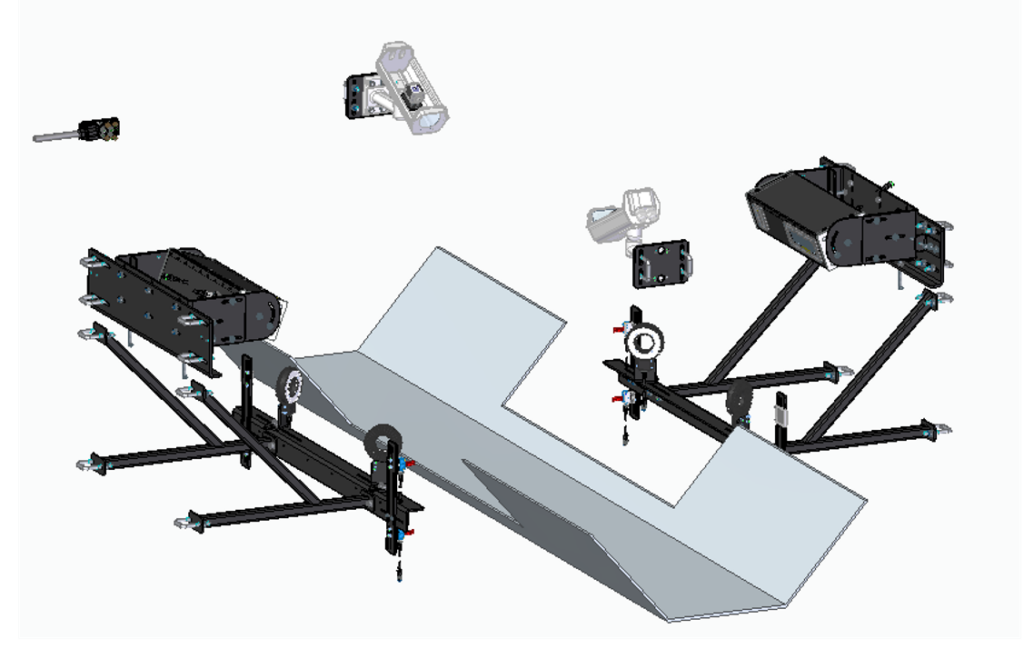

Precision measurement of the log

We have developed our own 3D module and various methods of measurement. We calculate diameters, length, volume, curvature. In addition, if needed, we can detect the thickness of the bark.

Detection of misaligned boards – we have created a solution for the wood industry production lines to identify boards that are skewed or incorrectly positioned. In case of detecting a misaligned board, a signal is given to stop the production line if necessary.