Leanest AI Scanner (AISC)

To remain competitive in an increasingly globalized market, the modern manufacturing industry requires efficient and reliable quality control systems.

In recent decades, detection solutions have developed rapidly – modern quality control is already largely a software solution.

With our innovative technologies, we offer industrial companies contemporary solutions that allow replacing the previously used quality determinations with more effective ones.

Until now, this role has been filled by human labor – with the help of AI technology, we are replacing routine manual work with an automated process.

Manufacturing Optimization

AI Solutions in Industry

Workforce Planning

Technology

In our quality detection software solutions for manufacturing industry, we have focused on AI solutions based on image recognition. We have specialized in image processing algorithms (image recognition) and machine learning.

Technologically we are using cameras and 3D lasers for capturing the material, applying additionally detection software that has been developed to artificial intelligence.

All solutions are built by us according to each customer unique needs and the choice of technology is made according to the conditions and requirements.

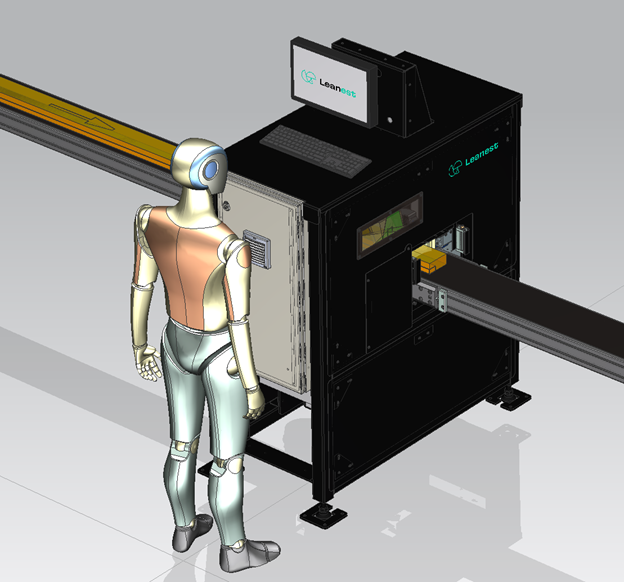

Leanest AI Scanner AISC

We have developed Leanest Scanner as a standard solution, significantly shortening project implementation time.

Leanest Quality Scanner employs artificial intelligence during operation, specifically trained on customer product and material-based data to detect visually identifiable quality deviations in products.

The device is designed to assess quality as the product moves longitudinally and is positioned between two conveyors. The compact device has a footprint of 550x1250mm.

Operator Workstation

The monitor can be the customer’s preferred display. As a standard option, we use a 15.6″ touchscreen monitor. The orientation of the monitor can be adjusted 180 degrees based on the position from which the scanner will operate and where the material’s zero line is located. For distance and angle adjustment, we use a standard VESA mount.

Material

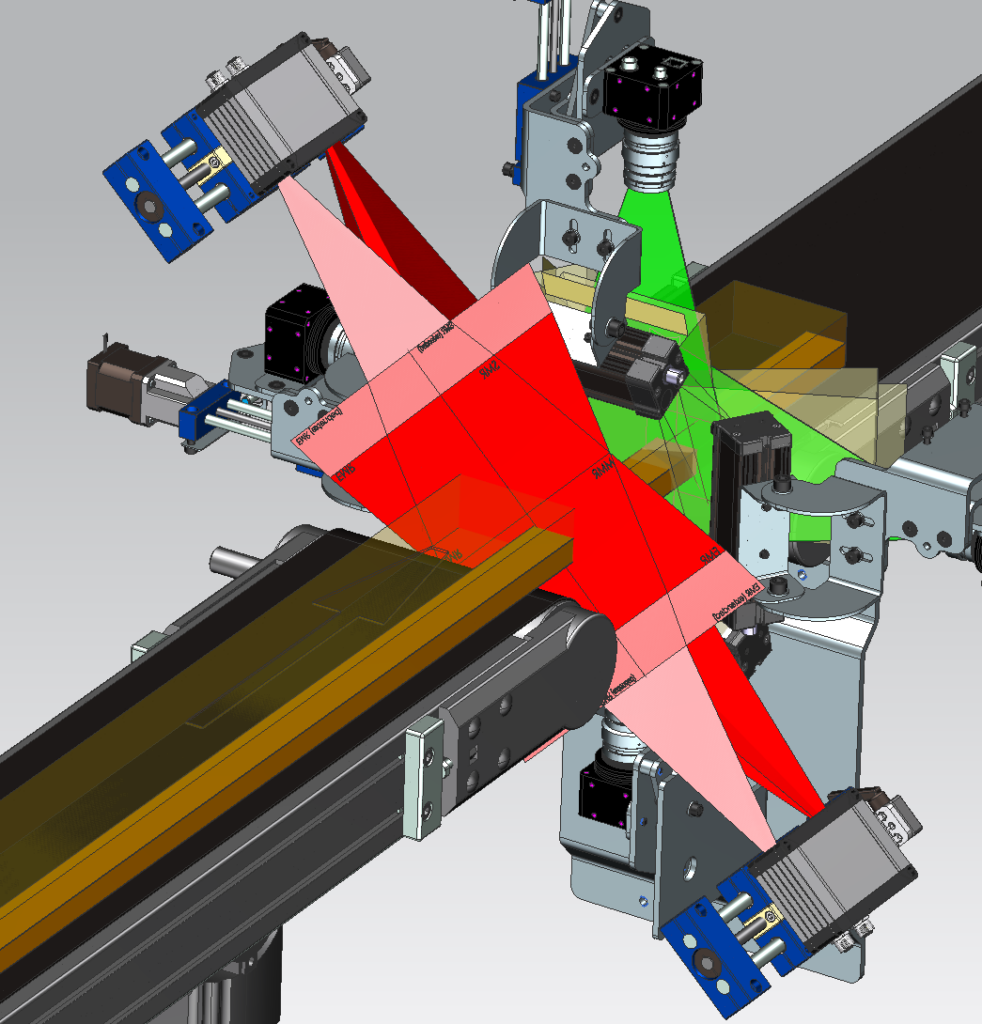

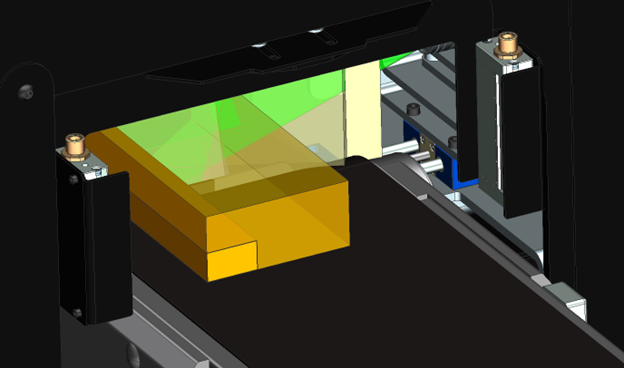

Depending on the cross-section of the material and the customer’s preference, we can design the placement and number of cameras for product inspection. We use a motorized stage to ensure the correct focal distance from the material at all times.

For inspecting the cross-section of the material, we can add appropriate lasers. We use red-colored lasers (also possible in blue) capable of operating at up to 10,000Hz.

Inspection can be carried out from all four sides, searching for characteristic objects on each side separately.

The aperture through which the material must pass is standardized at 260 x 100 mm, but depending on the product, the device can be adjusted.

Potential Use Cases

We apply artificial intelligence technology in areas where conventional ways could not keep up with the rising quality standards by the customers, e.g., in quality control jobs in the factories.

Some examples of potential use cases:

- Automatic sorting of material in the wood industry. Read more…

- Quality control in the metal industry

- Plastic sorting in the waste industry. Read more…

- Input material control in the food industry

- Quality control of products in the electronics industry.

- Quality control of packages/labels.

Based on the needs of each customer, we choose the best suitable AI solution.